FOOD PROCESSING

The Food Industry specifically uses Bunting® Magnetic Separation Systems, Material Handling Equipment, Metal Detection Equipment, Magnetic Cylinders, Bonded Magnets, and Assemblies. Our products can help you remove and transport the metals out of bakery goods, fruits, vegetables, meat, poultry, cooking oil and various other solid and liquid food products.

WOOD PROCESSING

Removing Metal Contamination from Wood Processing

- Overband Magnets – these magnetic separators sit over conveyors and lift larger ferrous metal contamination out of the conveyed shredded wood. Multi-pole designs reduce the risk of belt piercing from sharp pointed objects such as nails;

- Drum Magnets and Pulley Magnets – The Electro Drum Magnet or the Pulley Magnet provides enhanced ferrous metal separation, especially of smaller tramp ferrous metal. Due to the abrasive nature of metals such as nails, Drum Magnets are commonly supplied with manganese steel wear wraps;

- Eddy Current Separators – physically and continuously ejects non-ferrous metals (eg. aluminium door handles and hinges) out of the flow of the shredded wood;

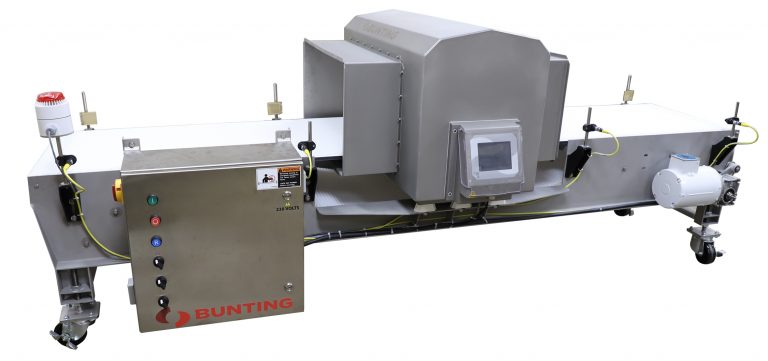

- Metal Detectors – mounted under and over conveyors to provide a final check prior to entering a shredder, and to check the final finished board usually prior to cutting. Specialist metal detector designs check complete logs for metal contamination prior to shredding;

Bunting Eddy Current Separators are available in 24″, 36″, 48″ and 60″ widths to provide non-ferrous conductive metal separation from non-conductive recycled materials. These are used extensively in the Plastics, Municipal, Electronics, Glass and Metal Recycling Industries to separate shredded aluminum, aluminum cans, bottle caps, hard drive housings and circuit board components into purer higher value product and metal streams.

These units can also be designed into “custom systems” in combinations with Transfer Conveyors into and out of the system, Magnetic Drum Separation Feeders, High Intensity Magnetic Separation Conveyors, Magnetic Crossbelt Conveyors and Vibratory Feeder Trays. Bunting Engineers will provide 3D System CAD Models and 2D dimensional drawings for system review analysis when orders are placed.

Vibratory Feeder (Optional)

Uniform single-layer feeding for maximum separation efficiency.

• Customizable widths and lengths to match application requirements

• Power supply and isolator designed to match flow requirements

• Can be fabricated in either mild steel or stainless steel

• Comes complete with controls and can be integrated into existing system